Spiral chip removal device is mainly used for metal non-metallic materials cut down the granular powdery lump and short crumbs of the transport. As the aircraft structure is compact take up a small space easy to install less transmission links reliable low failure rate propulsion speed selection range. Especially for the chip space is small other forms of chip removal is not easy to install the machine.

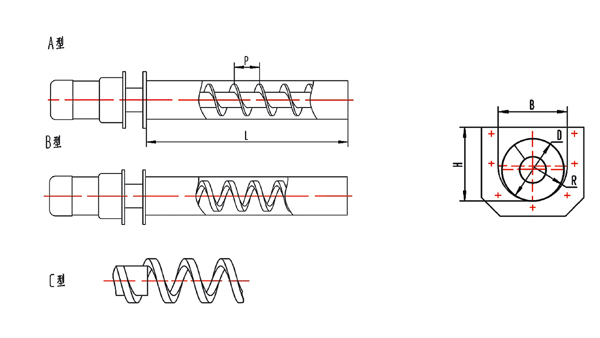

Spiral chip removal device is divided into three forms A type with rotating mandrel with chip flute; B-type without rotating mandrel with chip flute; C-type non-rotating mandrel no chip flute; Other chip removal devices are used together.

Spiral chip conveyor can be customized according to the requirements of the drawings but also according to your machine to provide the overall structure or pit design if necessary can also be measured on-site design.

| model |

Spiral outside diameter D |

Spiral blade thickness (type A) |

Chip flute width B |

Pitch P |

H | R |

L m |

Motor Power kw |

Chip volume kg/h |

| ZLLX70 | 70 | 4 | 80 | 70 | User defined | 40 | 0.6~3.00 | 0.1~0.2 | 70~100 |

| ZLLX80 | 80 | 90 | 80 | 45 | 0.6~5.00 | 0.1~0.4 | 90~130 | ||

| ZLLX100 | 100 | 6 | 120 | 100 | 60 | 0.8~8.00 | 0.1~0.75 | 120~180 | |

| ZLLX150 | 150 | 180 | 100 | 90 | 1.00~15.00 | 0.1~1.5 | 150~220 | ||

| Note: According to the size of the customer design and manufacturing | |||||||||